The great Multiwire in its most Compact and Intelligen version ever.

It is the most flexible machine among the GMW Series multiwire machines, which keeps intact the philosophy of reliability and robustness typical of Gaspari Menotti brand. SMARTWIRE GMW 06 multiwire machine has been designed to allow to simultaneously cut slabs of different thicknesses in a simple and precise way.

Do you need more information?

Contact us now or download the dedicated brochure.

Download brochure Request information-

The structure

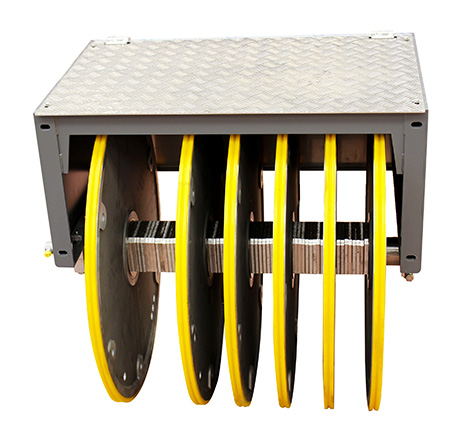

Multiwire SMARTWIRE GMW 06 is designed with a two-column structure along which the cursors that support the machine run. The motor side has a large diameter multi-groove flywheel, with a 10 mm pitch, driven by a belt transmission, while the tensioner side includes the tensioning pulleys, one for each wire, and a wire guide axis with independent pulleys for each wire.

Talk to an expertTalk to an expert

For more information about our services or for a free quote do not hesitate to contact us.

Request information -

Easy and precise regulation of the cutting thicknesses

GMW 06 multiwire machine is designed to allow to cut up to 5 slabs of different thicknesses. The distance between the wires can be easily set by inserting spacers between the flywheels of the wire guiding-drum and sliding the individual pulleys of the tensioner on the axes to which they are fixed to bring them in correspondence with the wire guiding flywheels. Once the operation is completed, it will be sufficient to move the wire on the corresponding groove of the motor drum.

Talk to an expertTalk to an expert

For more information about our services or for a free quote do not hesitate to contact us.

Request information -

The wires tensioning system

Each wire is individually tensioned by means of a pulley operated by a cylinder which is controlled by a proportional hydraulic system. During the working phases, the tension of the wires is monitored instant by instant through the management software, thus optimizing the cutting parameters as the materials treated vary and obtaining remarkable results both in terms of cost-effectiveness and reliability of the machine-wire system.

Talk to an expertTalk to an expert

For more information about our services or for a free quote do not hesitate to contact us.

Request information -

Electrical panel board and software: designed to serve the operator

The electrical panel is designed to be reliable and at the same time allow simple and quick maintenance. Inside there are a latest generation electronic and electromechanical components, while outside there is a “touch screen” display that allows the operator to communicate in a very intuitive way with the machine, keeping all the cutting parameters under control, such as, for example: down-feed speed, wire peripheral speed and tensioning of the wires, as well as the possibility to memorize the optimal cutting conditions for each material.

Talk to an expertTalk to an expert

For more information about our services or for a free quote do not hesitate to contact us.

Request information

Please fill in the form below. We will contact you as soon as possible!

Please fill in the form below and download the dedicated brochure.