Mirror slabs line polisher available in marble, granite and quartz versions, represents the vanguard in his category thanks to a solid and compact structure, an endearing design and last generation technological solutions.

-

A solid and compact structure

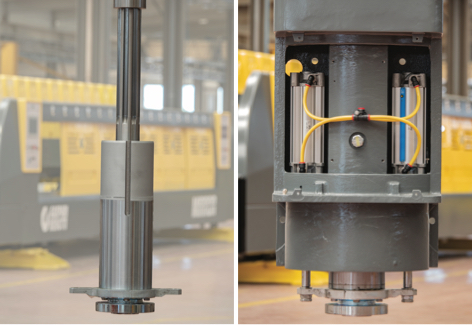

Bench and beam supports

The bench and the beam supports are built-in an electro-welded, monoblock steel structure studied through the Finite Element Method (FEM) to best respond to the mechanical stresses to which they are subjected.

In the bench, to maximize accuracy and planarity, all the surfaces related to the belt sliding have been processed with CNC machines.

In particular, the water discharges located on the two sides of working bench were modified to improve the drainage of water containing polishing residues, while the belt is constantly kept cleaned thanks to a washing unit with water jet and scrapers.

The conveyor belt movement is obtained by means of two large-diameter rollers driven by a brushless motor coupled to an epicyclical reduction gear.Spindle holding beam

The spindle holding beam is made of a monoblock structure built in electro-welded steel with a closed trapezoidal section that guarantees an extreme rigidity, as verified through the Finite Element Method (FEM), and at the same time containing of weight.

The spindles are located in the front face of the beam, increasing the rigidity of the whole system and improving its dynamicity.

In the rear part of the beam, in a position easy for inspection and maintenance operations, is located the accessories compartment where electro-electronic, pneumatic, lubrication and transmission controls are situated.

This compartment includes two reducers driven by brushless motors synchronized in electro-axis, which drive two units of rack and pinion systems, constantly grease lubricated.

The generous sizing of the motorization, added to the extreme rigidity of the structure, allows the beam to reach working speeds up to 75 m/min with reduced time of acceleration and deceleration, in order to improve the quality and the uniformity of the polishing results.

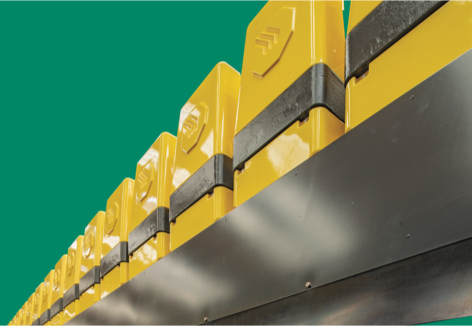

Polishing spindle group

The spindle body is made in cast iron, thus allowing a high rigidity and an exceptional capacity to absorb vibrations.

The “backpack” assembly of the spindle group helps to reduce length of spindle-shaft contributing to its rigidity.

This, combined with the large diameter twin pistons system, featuring counterpressure, and the minimum lifting of the heads from the slab surface, results in very fast up/down movements and consequently in polishing quality.

As a standard equipment, the working pressure of the heads is controlled by PLC through proportional valves.

The spindle is equipped with an automatic abrasive wear control system, which has the dual function of signalling the need to replace the abrasive itself and to ensure the minimum lifting of the head from the slab surface.

The use of particular design solutions and special materials allowed eliminating the necessity to lubricate the mechanical components of the spindle facilitating their maintenance.Safety protections

The safety guards system is composed by two different kinds of barriers:

– the first, consisting of soundproof and shatterproof sliding doors made of ABS sandwich and polyurethane foam, and equipped with a locking system that inhibits their opening while the machine is in operation;

– the second, consisting of an aluminium splashguard placed in front of the heads, equipped with automatic lifting for the change of the abrasives.

-

Electro-electronic architecture

Electro-electronic architecture

The new polishing machine is completely wired in FIELD BUS SYSTEM, with consequent simplification of the wiring, ensuring a reduction in the possibility of failures and, in case, a more rapid and punctual search for them.

We followed the guidelines indicated by “industry 4.0”, in order to make the machine already compatible with the new technologies.

In this view, all the installed sensors adopt the IO-Link standards, thus acquiring the capacity to talk to the main control and not only carrying out the task of detecting the measurements required but, at the same time, providing data on the state of efficiency of the various components.

The system has been developed in order to avoid breakages and machine stops through the request of preventive maintenance.

The user interface is designed to maximize its ease of use and encloses all the features needed to allow the access by remote.

Our customer service thus has the ability to connect directly to the software interface and to all the most important components such as drivers, safety PLC and inverters, in order to carry out a real time diagnosis and to guide the customer to the fault solution, reducing machine stops. -

The software

The software

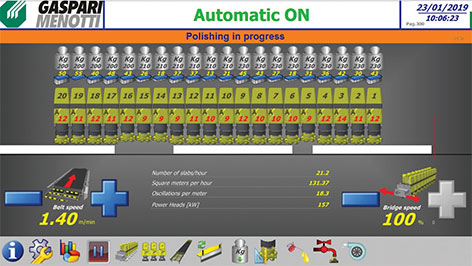

The software installed allows the operator to check, to program and, if necessary, to change the processing parameters of the machine in order to optimize the results of the finished product in terms of quantity and quality, in addition to collect data related to the operation of the machine itself.

The whole machine under control with a simple touch

The polishing machine is equipped with a coloured touch screen monitor with graphic interface, thanks to which it is possible to perform various functions including:

• Variation of the time that head stays on the slab surface acting on the descent / ascent times of the head itself

• Management of working pressure with possibility of dynamic variation inside the slab

• Management of beam speed and trajectory with particular regard to the inversion points

• Management of any breakage of slabs being processed with the possibility of modifying the profile red at the entrance of the slab itself

• Abrasive wear management

• Management of lubrication times and intervals

Statistics management: all production data displayed in real time

Thanks to a punctual and precise data collection it is possible to have, in real time, detailed information on all the processing parameters both cumulatively and for individual production lots.

Furthermore, it is possible to collect data relating to abrasives consumption.Alarm and diagnostic management: the health of your polishing machine in continuous monitoring

Through a series of sensors that adopt IO Link standards and a dedicated software module, all the main functions of the machine are continuously controlled and monitored on the screen in order to make the processing safe and to obtain information on the individual devices of the machine useful to generate a history of the problems and thus to accurately predict the average life of the individual components, making maintenance more and more precise, targeted and effective.

-

Accessories

Robot for loading and unloading of slabs

Completely automatic and equipped with a comb shape roller conveyor, it is used to load and unload the slabs, also allowing the slab to be worked “book-match” process. The robot is equipped with 54 suction cups and has a maximum capacity of 1.200 kg.

Automatic loading trolley for slabs

Equipped with 18 suction cups, it allows the loading of the slabs. The trolley has a maximum capacity of 1.000 kg. Vacuum pump with capacity 60 m³/hour.

Waxing machine for slabs

It allows the polished slab to be treated with protective wax, which is applied to the surface of the slab itself using plates equipped with special brushes

Automatic unloading trolley for slabs

Tilting type, capacity 1.000 kg., unloading of the slabs by hydraulic slides.

Automatic system of slab centering.

Semiautomatic loading and unloading trolley

Capacity 1.000 kg. Equipped with motorized wheels and rollers, hydraulic tilting system, electric panel on the side of the machine, wired remote control, 6 m. of rails included.

Slabs profile reader

It is a fixed electronic device, which reads the shape of the slabs without any physical contact and independently from the slabs thickness.

Blower to dry the slabs

Polygonal blower to dry the slabs, power 3 kW.

Automatic applicator of thermoplastic polymer

Machine designed for the application of anti-scratch plastic cords on the surface of the polished slab. It is supplied with electrical control panel.