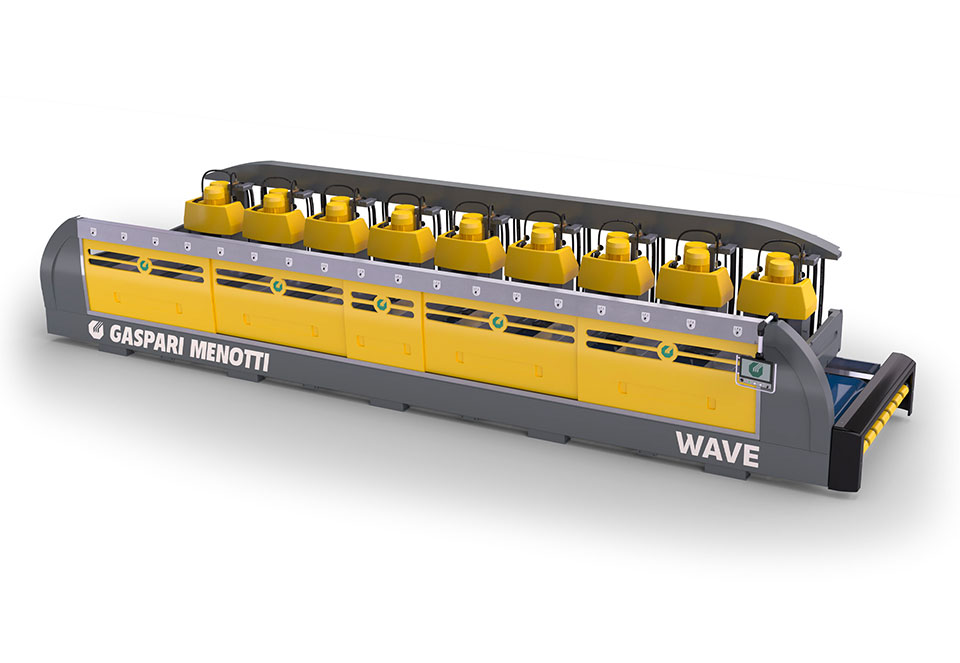

Polishing marble slabs requires continuous improvements to increase the quality of the slab surface, even in the case of slabs with an irregular perimeter. The evolution of technology has led to the creation of increasingly high- performance machines and the search for innovative solutions to obtain perfect polishing over the entire surface of the slab. From these needs, the new WAVE polishing machine from Gaspari Menotti Technologies was born.

-

Bench and bridges supports

The basic concepts of Gaspari Menotti’s construction philosophy are maintained in the structure of WAVE polishing machine, with the bench and spindle bridges that have been designed and calculated using the FEM finite element calculation system and are made of electro- welded monoblock steel structure. The bench is processed with CNC machines to ensure the perfect flatness of its contact surface with the belt carrying the slabs.

-

Spindle holding bridges

One of the features of WAVE polishing machine is that it has the spindles mounted in pairs on individual bridges; therefore, the machine will have a number of beams equal to half the number of spindles installed.

The solution adopted makes it possible to minimise, compared to traditional machines, the lifting of the abrasive plates from the surface of the slab in the case of slabs with an irregular profile. Simultaneously, the time to change format is also reduced, which will be equal to the time required to pass a slab under a pair of mandrels. -

Software and electric board

The electric board is designed by adopting the FIELD BUS system to simplify wiring. Furthermore, “Industry 4.0” guidelines were followed in its design, with the adoption of IO-Link sensors. WAVE polishing machine software has a dedicated section that allows the pairs of spindles to be moved independently for the most difficult machining operations, to standardise and align the movement of all the spindles, as in traditional polishers, or to align only some of the pairs of spindles, leaving the other pairs of spindles of the polisher free to move independently.

By selecting the mode that provides for the independent movement of the pairs of spindles, WAVE polisher is able to exploit the regenerated electric current, thus reducing electricity consumption.